Converting plant waste into biofuel

Two faculty members in the School of Engineering & Applied Science are teaming up to find a way to turn a waste product from wood into biofuel and biomaterials

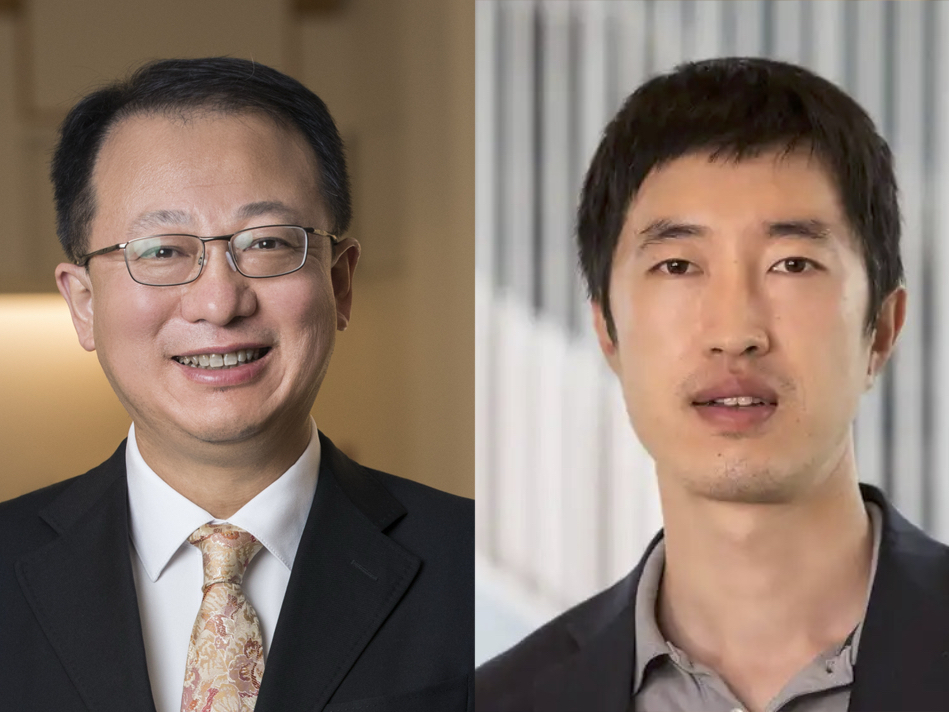

Tae Seok Moon, PhD, and Marcus Foston, PhD, both assistant professors in Energy, Environmental & Chemical Engineering, are blending their areas of expertise to convert lignin, a recalcitrant polymer that gives plants their structure, into a fat that can be used as a biodiesel precursor. They are co-principal investigators of a one-year grant received from the university’s International Center for Advanced Renewable Energy & Sustainability (I-CARES).

Foston’s expertise is in breaking down lignin, a by-product of paper and ethanol production, into phenolic compounds. Moon’s expertise is in engineering bacteria. For the I-CARES project, Moon is engineering a bacterial strain, Rhodoccocus opacus, and using it as a catalyst to convert lignin phenolyics into triacylglycerols (TAGs).

One-third of plant biomass is lignin, Foston says, and it is usually thrown away or burned as process heat. Other researchers have stayed away from using lignin because it’s so difficult to break down.

“We’re going to take a material that is considered waste, for which there is no cost to recover, and make it into a high value-added product,” Foston says. “Not just biofuel, but materials and chemicals as well.

“This has never been done before,” Foston says. “This particular project will be a system in which we have a broader platform to produce a wide array of materials from lignin.”

Foston converted lignin into monomer components, but these monomers can be toxic, especially to bacteria. That’s where Moon’s expertise comes into play. He engineered the bacterium Rhodoccocus opacus to make it tolerant to the toxic monomers generated from lignin.

Rhodoccocus opacus is originally isolated in a contaminated soil, so it evolved to obtain the ability to be tolerant to the toxic chemicals and to use the toxins as an energy and carbon source, Moon says.

“So far, we have achieved an almost seven-fold improvement in tolerance of the bacterium to the phenolic compounds,” Moon says. “What we did is simply accelerate the evolution process,” he says.

Foston says this system has the potential to go further. “The nice thing about metabolic engineering is that if we can get bacteria to make one thing, we can get them to make other things,” Foston says. “If we understand the pathway, we can change the genes of the bacteria to make other things.”