In the media: From emergency ventilators to intubation hoods, local makers find new purpose during COVID-19

Creative efforts continue to assist frontline health-care workers

As the number of COVID-19 cases increased in the St. Louis area, Washington University launched its Maker Task Force to create equipment and technology needed by hospitals or frontline workers during the pandemic.

The force's executive team spanned members of various disciplines and backgrounds affiliated with the university. It included Thomas M. Maddox, a professor of medicine and executive director of the BJC/WUSM Healthcare Innovation Lab; Ali Kosydor, the lab’s director of operations; Aaron Bobick, dean of the McKelvey School of Engineering; Eric Leuthardt, a professor of neurological surgery and inventor; and Philip Bayly, chair of mechanical engineering and materials science.

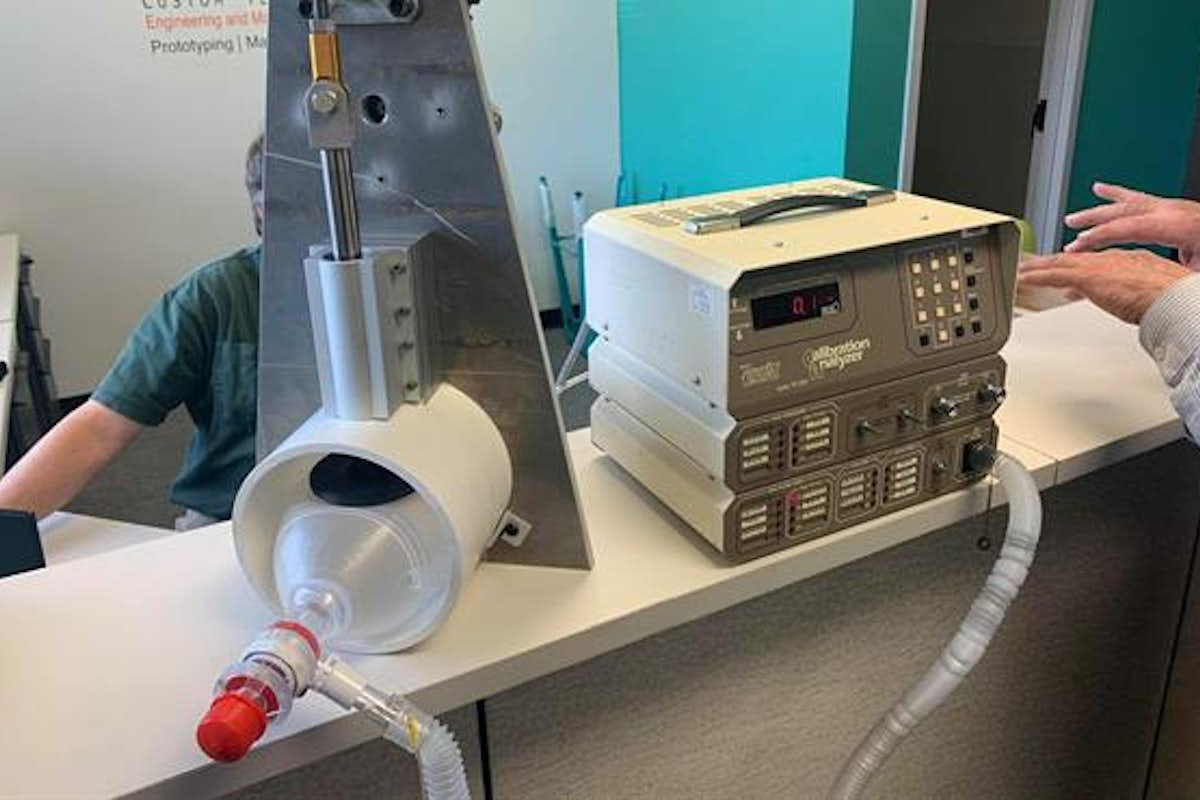

The initiative joined others on the campus who had access to “equipment such as 3-D printers or laser cutters to make simple things to protect frontline workers,” Bayly says. They set out to make isolation gowns, surgical masks, face shields, N95 respirators and methods to disinfect them, and emergency ventilators and replacement parts.

“One of the next things we did was sit down and brainstormed: What are the needs? What are people running low of, here or nationally? What do we need to be thinking about? One of the things that rose to the surface quickly in the discussions was ventilators,” Bayly says.

So he looked into it and reached out to his former student Jerry Halley, who is now chief engineer at a local aerospace parts manufacturer. “I knew he was one of the best engineers who understood manufacturing, so I thought he'd be an ideal person to help us figure out how to make something quickly and inexpensively—but most importantly quickly—that might help us address a shortage in ventilators.” Looking for someone who understood electronics, they tapped Dennis Mell, an electrical engineer and professor at Wash. U., and pulled in machinist John Kreitler, of the Instrument Machine Shop at the School of Medicine where four other employees would work on the portable ventilators.

>> Read the full article in St. Louis Magazine