‘Elegance in simplicity:’ A prototype is born

McKelvey School of Engineering students designed prototypes for a device that could help monitor the air quality impact of Missouri factory farms

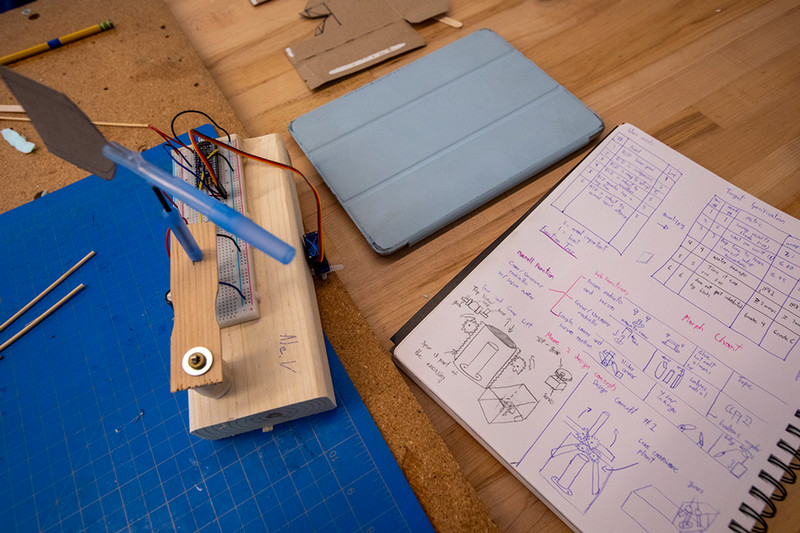

Students in the McKelvey School of Engineering at Washington University in St. Louis designed prototypes for a device that could help environmental engineers monitor the air quality impact of factory farms in Missouri. The students built their prototypes in the Spartan Light Metal Products Makerspace in Jubel Hall over the course of the fall 2023 semester.

Working with lecturer Jackson Potter, undergraduate students in the upper-level “Multidisciplinary Design & Prototyping” class (MEMS 312) developed their prototypes to meet a need described by environmental engineers in Jay Turner’s research group. Turner is the James McKelvey Professor of Engineering Education.

While much of the nation’s animal agriculture production once occurred in open fields, today most animals raised for human consumption live in Concentrated Animal Feeding Operations, or CAFOs. If not designed or managed properly, these intensive farming operations can pollute local air and water. People who live or work near CAFOs, especially those who spend a lot of time downwind of them, experience the brunt of the negative impacts.

“Basically it stinks — in one direction,” said Celine Vuong, an undergraduate student who developed one of the prototypes, along with her class partner, Jaimie Lin.

In September, Potter invited the Turner group researchers to visit his class and describe the simple and low-cost air quality monitoring devices they are installing at properties adjacent to CAFOs. The scientists needed a way to shield their sensitive sampling equipment until the wind picks up in the “right” — or, depending on your perspective, “wrong” — direction, ie, from the farm. The researchers wanted their sensors to remain open, or exposed, while the wind blows directly from the farm, and cover the sensors when the wind shifts to a different direction.

Over the fall semester, the students grappled with many decisions related to their prototypes: Is it better to 3D-print something, or to export a 2D pattern and have a machine cut the needed part out of an existing pane of plastic? Which solution is going to be airtight? How many batteries are needed to operate the mechanism? And, at a practical level, what happens when the 3D printing queue at the makerspace gets too long?

Ultimately, the students pictured their internal customers as they made their final design choices. “You want to make it easy for the people who will install it,” Vuong said. “There’s lots of things to consider.”

Read the full story here.