In the media: Creating Synthetic Silk from Microbes

Engineered bacteria produce silk-like fibers that are as strong as natural ones

>> Read the full article on Scientific American

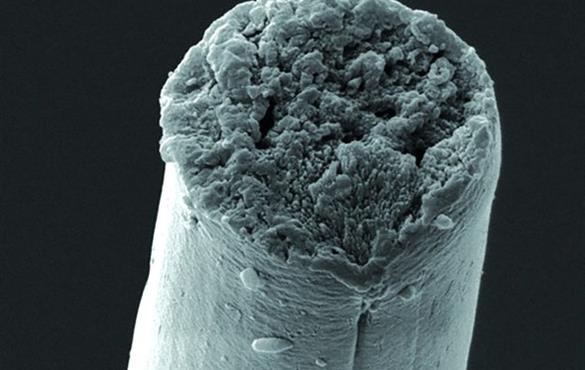

Spiders spin the stuff of engineers’ dreams. Their silk is as strong as steel, stretchy, nontoxic and biodegradable. But spiders are not easy to farm. Each produces only a minuscule amount of silk, and some are cannibalistic. For decades scientists have tried to mimic the silvery strands to use for sutures, athletic gear and bulletproof vests, but their synthetic fibers have fallen short. Now a team has coaxed bacteria to produce silk as tough and elastic as the natural version.

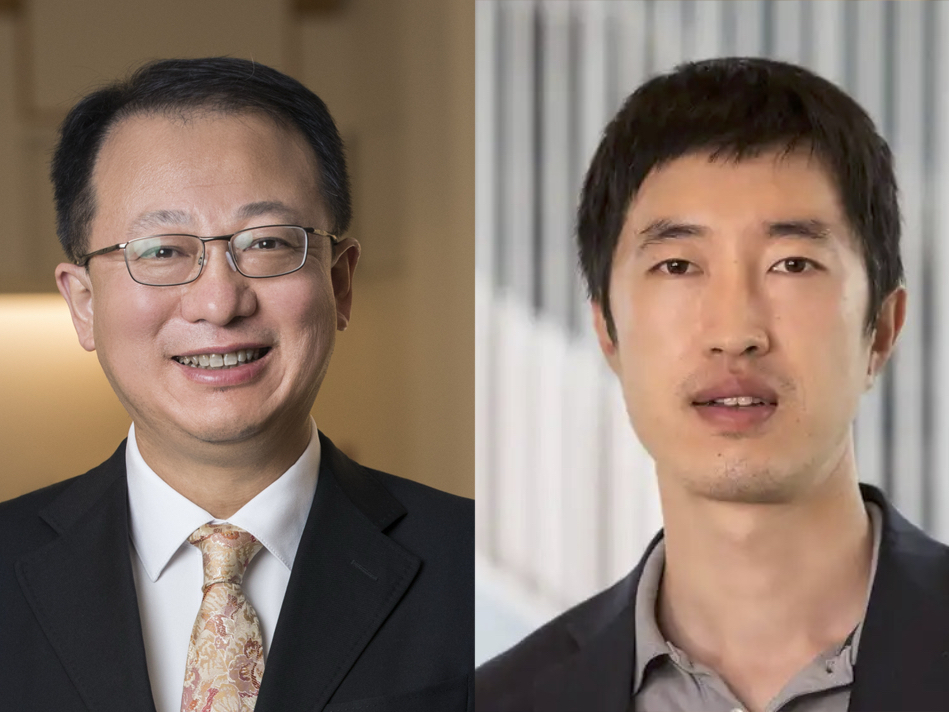

Researchers have previously transplanted silk-making DNA from spiders into bacteria, silkworms, plants and even goats in an effort to mass-produce the substance. Until now, however, the best engineered fibers have been only half as strong as the real thing. The secret to spider silk’s strength lies in large protein molecules composed of hundreds of strings of repeated amino acids encoded by similarly lengthy, repetitive DNA sequences. But “in general, nature does not like repetitive DNA and finds ways to get rid of it,” says Fuzhong Zhang, a professor of energy, environmental and chemical engineering at Washington University in St. Louis. Spiders have figured out how to stabilize the large DNA—but in other creatures, such repeated units get snipped or changed.To circumvent this problem, Zhang and his colleagues modified the spider DNA involved in producing silk proteins. Microbes engineered with this modified DNA make silk protein molecules with a unique “tag.” The tags glue together two molecules to form the desired long chain and then fall off. The resulting proteins are longer than the largest natural proteins. The researchers made these proteins into a powder and mixed it into a solution that can be spun into fibers as strong as natural ones, they reported in September in Biomacromolecules.

Synthetic silk could be a sustainable alternative to petroleum-derived fibers such as nylon, Zhang says. But the challenge is producing it in sufficient quantities at low cost. The new approach may still face the same issue because the spinning solution is made with a corrosive and costly solvent, says Gregory Holland, a professor of chemistry and biochemistry at San Diego State University, who was not involved in the work. “The next step,” Holland says, “is working on [a water-based] solution to see if similar high-performance fibers can be produced.”