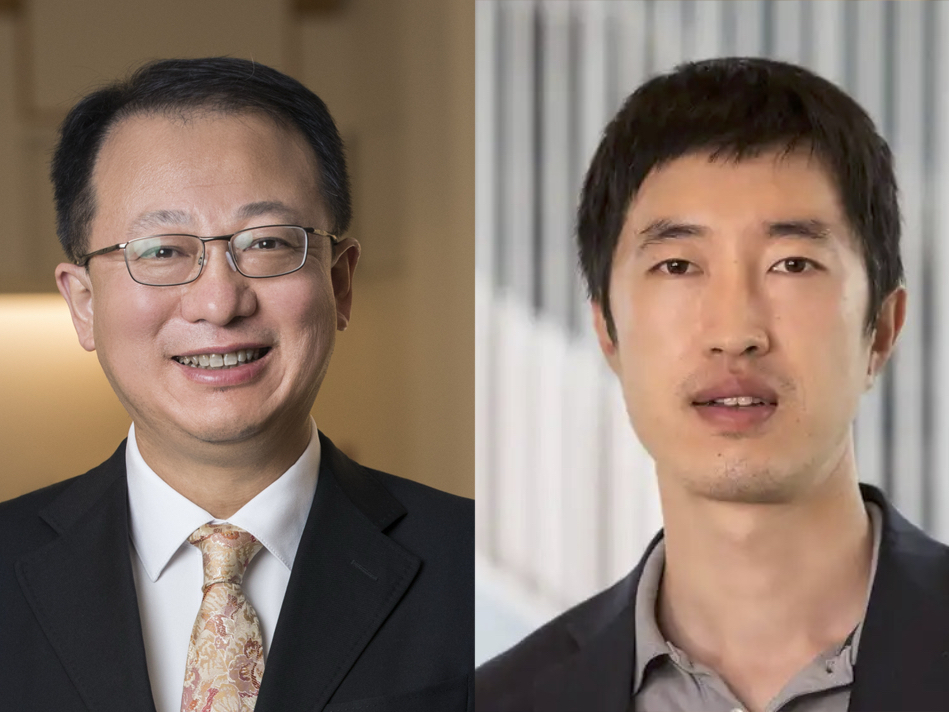

Research from the lab of Peng Bai, assistant professor of energy, environmental & chemical engineering at the McKelvey School of Engineering at Washington University in St. Louis, recently revealed the formula for building a perfectly stable sodium electrode.

The team has now discovered the formula for a perfectly stable and safe electrode.

The research was published last month in the journal Advanced Energy Materials.

Stability in an electrode is key to a well-performing battery. Instability is caused by irregular distribution of metal ions as they move from the cathode to the anode. The more uniformly the ions move, the smoother the outgrowth of metal deposits. This results in a longer-lasting battery and, importantly, a battery that is less likely to short and create a hazardous situation.

“Does absolute stability guarantee absolute safety?” Bai asked. It does not, especially during the fast charging. Bai and Bingyuan Ma, a postgraduate research associate, determined why.

The short answer: A critical component that has been left out in laboratory experiments is more important than previously thought. A perfectly safe battery that can undergo fast recharging requires cooperation from the separator.

When researchers observe the changes of metal anodes in real-time during battery fast charging, they do it in a lab setup that leaves out the separator, which is a crucial part of the battery. This porous divider separates the anode side from the cathode side of a battery. It turns out that the separator plays an outsized role in how safe a battery is, no matter the stability of its electrode.

“We found that safety depends on the pore size of the separator,” Bai said. Battery separators are porous in order to hold liquid electrolytes for metal ions to move, but some have bigger pores than others. “The lower the pore size, the lower the chance of localized pore selection by the growing metal deposits.”

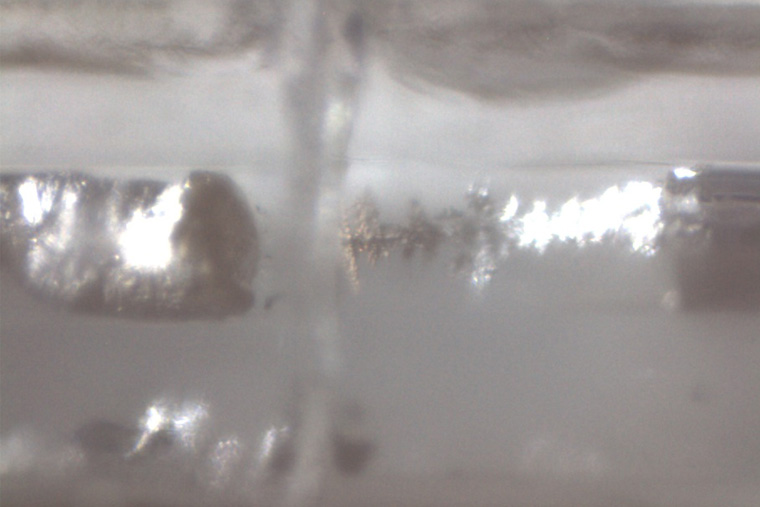

Sodium (NA) penetrating a layer of the separator

That means that as the electrode moves toward the separator, if the pore sizes are small, there are fewer places the metal ions can penetrate. Instead of evenly spreading out, much of the current ends up in some naturally selected spots, which can lead to a battery short circuiting.

Bai and Ma have devised a mathematical model, called the Young-Laplace overpotential, that captures the dynamics of the physics inside an actual battery, which is now guiding Bai’s lab to develop more stable and safer anode-free metal batteries.

“We had already found a physical threshold for the ideal cases,” Bai said. “But the practical threshold is much lower. And it depends on the microstructure of the separator precisely following the mathematical model we developed.”

This work was supported by a National Science Foundation grant (Award No. 1934122). The materials characterization experiments were partially supported by IMSE (Institute of Materials Science and 56 Engineering) and by a grant from InCEES (International Center for Energy, Environment and Sustainability) at Washington University in Saint Louis. P.B. acknowledges the startup support from Washington University in St. Louis.

The McKelvey School of Engineering at Washington University in St. Louis promotes independent inquiry and education with an emphasis on scientific excellence, innovation and collaboration without boundaries. McKelvey Engineering has top-ranked research and graduate programs across departments, particularly in biomedical engineering, environmental engineering and computing, and has one of the most selective undergraduate programs in the country. With 165 full-time faculty, 1,524 undergraduate students, 1,554 graduate students and 22,000 living alumni, we are working to solve some of society’s greatest challenges; to prepare students to become leaders and innovate throughout their careers; and to be a catalyst of economic development for the St. Louis region and beyond.

Click on the topics below for more stories in those areas

Back to News