The future is brewed

Brewing is an old science, but offers glimpse into plastic-free future

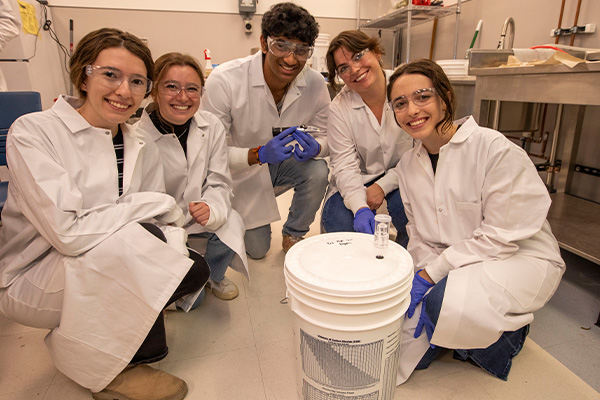

Washington University in St. Louis students gathered among gleaming stainless-steel tanks to learn a lesson in bioproduction from Kurt Driesner, manager of quality and process at Urban Chestnut Brewing Co. in St. Louis. In a previous class, Driesner reminded students that technically, humans have never “made” beer, but rather, it’s the yeast that finish the crucial final step in taking the slop of core ingredients and fermenting the sugars into something tasty.

But microbes are finicky employees, who are not thrilled with the part of the brewing process where they are deprived of oxygen.

“At the end of the day, it’s alive,” Driesner reminded them.

These future engineers will do well to remember that fact. The science of brewing, called zymurgy, is almost as old as civilization, but as technology advances, beer is not the only thing these students may be brewing in the future.

The McKelvey School of Engineering at Washington University has been investing talent in the “circular economy,” a system in which products never become waste, and materials are reused or composted so nature is regenerated.

Its newly unveiled Synthetic Biology Manufacturing of Advanced Materials Research Center (SMARC) will be a destination for the creation of such products. Marcus Foston, an associate professor of energy, environmental and chemical engineering, is the center’s director, and Fuzhong Zhang, a professor of energy, environmental and chemical engineering, is the co-director.

The undergraduate students in WashU’s zymurgy class can see the practical application of that vision through the traditional science of beer brewing. As the circular economy becomes reality, there will be many more jobs involving microbe wrangling, bioreactor engineering, synthetic biology programming and problem-solving ways to scale up all this technology.

Driesner, a former toxicologist, can speak to that challenge.

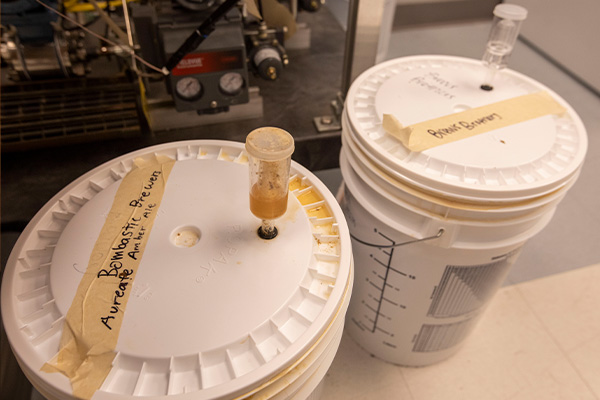

“Nothing scales, nothing ever scales,” he said to students about their home-brew recipes. The class runs students through three batches of the brewing process.

“If you take that same recipe and just try to scale it up to 50 barrels, 60 barrels, it won’t work in the slightest.”

Adjustments must be made in engineered systems, but it’s not about adding tech for tech’s sake, he warned. Brewing is an ancient science, and technicians such as Driesner have respect for the old ways of doing things. WashU students can learn from that as well.

“It’s one of the oldest forms of biomanufacturing,” Foston said about brewing. SMARC research and brewing science align in that it’s all about “how to use biology to manufacture materials,” he added.

The zymurgy class grows ever more popular at WashU because it’s fun to brew beer, but its practical applications of chemical engineering principles bring something much more valuable to the table. Chemical engineering majors get first pick, but the class is available to any undergraduate engineering student. They increased the size this year to accommodate 20 students, but the waiting list remains long.

Students can see how this bioproduct is made at various scales, from troubleshooting their home-brew setups in the lab; to tours of a small craft brewer in Florissant; the visit to medium-scale producer Urban Chestnut; and, finally, a tour of Anheuser-Busch InBev to see a much larger scale of production.

“They get the hands-on experience, but at the same time they reinforce what they’ve learned in class,” said Vijay Ramani, vice provost for graduate education and international affairs and the Roma B. & Raymond H. Wittcoff Distinguished University Professor, who co-teaches the class with Ray Ehrhard, a senior lecturer.

“We do focus on the chemical engineering principles that are useful in this process,” Ramani said, as he readied a lecture on heat-transfer principles. “It’s a very practical class.”

A “bioreactor” is another way to describe those stainless-steel tanks full of “bugs” (yeast or bacteria). Yeast may be our main brewers, but they’re not the only microbial employees in town.

There are examples of “bugs in tanks” beyond the yeast at breweries, said Ramani, adding that Anheuser-Busch makes use of bacteria in treating its wastewater on-site as well, called bioremediation.

These practicalities are another crucial part of the learning process because engineering is not just about developing new technologies, but also understanding the markets and unforeseen effects of that tech. There are inputs and outputs to account for, such as figuring out a carbon-neutral feedstock for those bugs in tanks and coming up with a plan for the waste produced and how consumers interact with that final product.

Jean Brownell, an assistant in instruction for the zymurgy class, ended up returning to school to study environmental engineering thanks in part to her time working a variety of positions at Anheuser-Busch, including focusing on water quality and sustainability.

“They have a lot of systems centered around water quality there,” said Brownell, who is working on her PhD at WashU, studying herbicide volatility in McKelvey Engineering’s Department of Energy, Environmental & Chemical Engineering.

Bioremediation systems not only account for the waste but can help the bottom line as well. One way is by harvesting the methane off-gassed by the microbes and using that methane to run boilers. Brownell said Ehrhard and Ramani have done a good job designing the class so students can both see those details but not get overwhelmed in the weeds of beer science.

“It’s a really cool way to show how practical the engineering classes they’re taking are and what that looks like in real-world applications,” she said.

Watching how professionals like Driesner handle their work, students can see that, even for a craft that is thousands of years old, there are always kinks to work out. Engineers can come up with a great solution for one problem, but they need to think ahead if it might cause a problem downstream.

For instance, Urban Chestnut made 72 different styles of beer one year. A one-size-fits-all solution for fermentation would not work for that.

“There is no engineering solution for 72 different styles,” Driesner said. “The solution is flexibility.”

Beyond beer

With a five-year $3.6 million Growing Convergence Research grant from the National Science Foundation, the SMARC team plans to develop a new class of biologically synthesized, protein-based and biodegradable materials, made in part by genetically engineered microbes.

Both Foston and Zhang emphasized that SMARC is multidisciplinary because replacing fossil fuel-based plastic is not as simple as coming up with bio-goo to replace it: it needs to be affordable to make and easy to use.

The earliest versions of biomaterials will likely be for high-end products with specific, high-performance requirements.

“It would be a proving ground for the technology,” Foston said.

Zhang’s lab likely will follow that path, as he and colleagues inch toward more efficient production of super silk fibers. Instead of silkworms, the fiber factory comes from genetically modified E.coli in bioreactors.

There is a learning curve in bringing new tech to society, and “it takes some amount of trial and error to get there,” Foston said.

It’s why SMARC straddles multiple disciplines and plans partnerships with the Sam Fox School of Design & Visual Arts and Olin Business School to make sure the targets they pick are economically viable.

“Ultimately, we can make a great product, but if people don’t adopt that product, then it won’t have the impact we want it to have,” Foston said.

The zymurgy class shows students how engineering fits into the broader scope of “people problems,” he added. “Understanding both motivations and barriers for a transition to bioplastics is going to be super critical.”