Electronics transformed

Alumnus Tyler Richards goes from ‘tinkering’ to tackling complex challenges

For Tyler Richards, who earned a bachelor’s degree in electrical engineering from McKelvey School of Engineering in 2022, a high school hobby set the stage for a career with purpose.

Richards started designing circuit boards on a freelance basis at 15, connecting with customers online and completing hardware for them in his own home.

“I've actually been tinkering with electronics since 8th grade,” he said. “And as I got older, I realized this was better than getting a ‘real job.’”

Over the years, he has helped numerous organizations transform ideas into tangible products, assisting clients with designing, developing, making prototypes and manufacturing their electronic hardware. His portfolio includes a wide range of innovative projects, such as plant growth chambers, 3D printers and music synthesizers.

When the COVID pandemic hit in 2020, Richards struggled to find the parts he needed.

“The pandemic started me on the path of being able to make my own circuit boards,” he said.

Being in a “COVID bubble” eliminated distractions and gave Richards the time and focus he needed to work on projects and develop the idea of in-house, rapid circuit board printing. It also changed the way he viewed his future career.

“Before COVID, I saw the track as being to go to college and then get a corporate job,” he said. “Yes, COVID was a disaster, but it made me think, ‘If everything is already messed up, why not try something new? How could things get worse?’”

Richards’ new perspective ultimately led to the creation of uFab, a business dedicated to a faster, environmentally friendlier way to make printed circuit boards (PCBs), which act as the foundations for electronic components in devices like phones, computers and appliances.

Thanks to an angel investor and a $75,000 Arch Grant follow-on investment, Richards was able to "graduate with capital, not take a job, and test this ultra-rapid laser manufacturing prototype.”

“The same way 3D printers speed up prototypes of mechanical hardware, we are doing the same thing for electronics,” Richards said. “Instead of three weeks, we can have a finished board in under four hours, with U.S. delivery in 24 hours.”

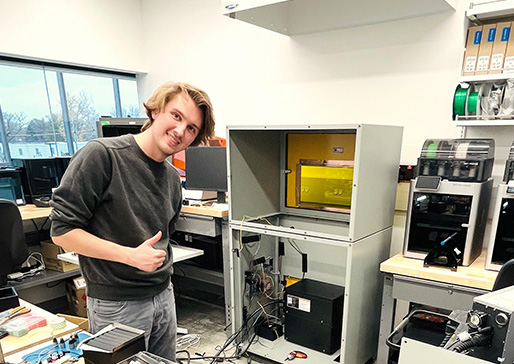

The key to making this happen? The PCBee, uFab’s flagship PCB manufacturing machine.

Richards says that while uFab sells prototypes for PCBs, “at some point owning the machine itself in house just makes sense.” This is especially true for those with large-scale needs or those concerned about third-party leaks of their design files.

In 2023, uFab established a collaboration with the Neurotech Hub housed in the Neuroscience Research Building at Washington University School of Medicine. Circuit boards are used extensively in neuroscience research for a variety of applications, and the PCBee makes it possible for the Hub to rapidly provide custom devices for researchers in the neuroscience community.

In addition to speed, the technology allows printing on a variety of substrates, including flex, ceramics, aluminum and more, making it applicable to an array of applications, from wearable tech, to aerospace, to high-end research.

But it’s the environmental benefit that Richards calls a “game changer for the electronics industry.

“This is generally a slow, expensive process focused on mass manufacturing with noxious chemicals,” he said. “That’s why most of this business has gone overseas where the safety and environmental regulations are lacking.”

UFab’s patent-pending way of manufacturing PCBs uses lasers instead of chemicals, eliminating the use of acids. Typically, manufacturers “have to hire a chemical waste disposal company to get rid of these highly toxic chemicals, which is a huge, expensive process,” Richards says. “The hope is to adapt the laser technology to traditional large format printing and eliminate chemical etchants altogether.”

In April, uFab was one of three St. Louis startups to receive a $50,000 WashU Venture Network Follow-on Investment through a partnership between the Skandalaris Center and the In St. Louis, For St. Louis initiative. The investments support ventures that are ready to scale and show promise to make a meaningful impact in the St. Louis region.

Richards is proud to continue his connections to a city – and a school – that have been central to his success.

“We’re doing production out of a 1,400-square-foot facility in St. Louis, and we’re matching the productivity of a larger facility without generating any chemical waste,” he said.

Moving forward, he hopes to hire additional employees from WashU and Ranken Technical Institute.

“The hope is to bring these manufacturing jobs to St. Louis specifically,” Richards said. “But we’re going to do it in a way that isn't detrimental to workers or the environment.”