It's easy to start your application.

COVID-19 WashU/BJC Maker Task Force (MTF)

Face Shields, Masks & PAPRs

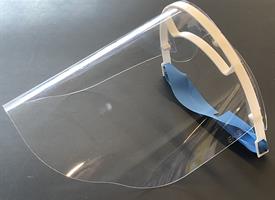

Face Shields

"The WashU Shield" (download design files), developed in the Spartan Light Metal Products Makerspace, is the preferred design when standard issued ones are not available.

"The WashU Shield" (download design files), developed in the Spartan Light Metal Products Makerspace, is the preferred design when standard issued ones are not available.

A WashU designed strap adapter for 3D printed face shields has been approved by the NIH for emergency use. https://3dprint.nih.gov/discover/3dpx-014017

Related news stories:

- McKelvey Engineering staff creating face shields for health care workers

- 3D printers inside closed schools are working overtime to make masks

It is a modification of a design posted by the 3D printer maker PRUSA. The modifications:

- Make it faster to fabricate on standard 3D printers and laser cutters

- Provide slightly more flexibility for comfort

- Extend lateral coverage of the face shields

- Include a shield and visor attached inside the head band frame to prevent exposed holes in shield

- Adds curved top “visor” piece that bends to fit against different forehead shapes for droplet protection from above

- Includes an adjustable head strap

- Enable shield to be completely wiped or washed for reuse.

The following designs have already been approved by the NIH 3D print exchange.

- NIH 3D Printable Headband for Face Shield

- Surgical Mask Tension Release Band for Ear Comfort & Extended Use

Cloth & Isolation Masks

The Maker Task Force sent two mask prototypes to BJC Supply Chain for manufacturer review and contracting. One is a simple isolation-style mask and the other is a simple duckbill-style mask. After clinical evaluation, the duckbill was chosen as the preferred style as it allows for easier breathing.

Aside from the shelf-ready prototypes, the Maker Task Force identified a local manufacturer to produce 70,000 cloth masks in order to provide each BJC employee with two masks.

For both masks, at least two layers were recommended, preferably three. Combination suggestions:

- 2 layers: Layer 1=polyester crepe with textured filament yarn, Layer 2: 100% linen

- 2 layers: Layer 1= polyester crepe with textured filament yarn, Layer 2: Pellon polyester fiberweb

- 3 Layers: Layer 1=polyester crepe with textured filament yarn, Layer 2: Pellon polyester

Disinfection

The Disinfection subgroup implemented a process to disinfect disposable N95 respirator masks that allow health care workers to reuse their own masks for up to 20 cycles using vaporized hydrogen peroxide. The group disinfected 3000+ N95 masks in the weeks following the COVID-19 outbreak and has the capability of disinfecting up to 1,500 masks daily.

Related news stories: