It's easy to start your application.

COVID-19 WashU/BJC Maker Task Force (MTF)

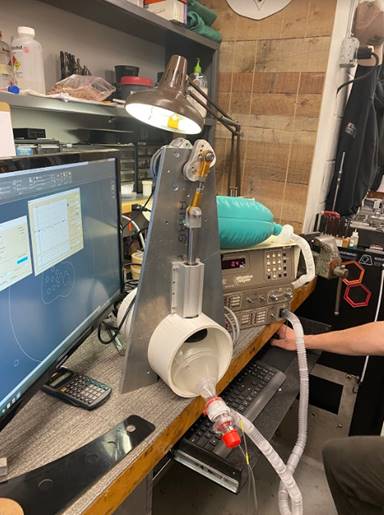

Ventilators

Within two weeks, a "1st generation" emergency ventilator ("AmbuVent") prototype was completed, with control of tidal volume, breathing rate, and inhale/exhale timing. The device was calibrated and tested in the clinical simulation lab. Feedback from medical staff was used to improve the design, including electronic calibration and safety limits. Three "2nd generation" prototypes have been assembled with a touchscreen interface for control of breathing rate, tidal volume, and inhale/exhale ratio.

The MTF will continue testing and evaluation with the three 2nd generation prototypes. Proposed enhancements include a pressure sensor to allow the device to respond to patient breathing. MTF will seek broader evaluation and clinician feedback on the 2nd generation prototypes.

From projections shared with the MTF, it appears that vent capacity can be met at BJC without emergency ventilators. The MTF is following through on this option in case an unexpected need arises, or to guide/assist with ventilator needs in other locations.

Related news stories:

- Eclectic St. Louis team of doctors, engineers and machinists answers call for emergency ventilators

- Local makers find new purpose fabricating intubation hoods and emergency ventilators during COVID-19

The following videos show the prototypes in action:

- Emergency Vent Demo (courtesy of Jerry Halley, Tech Manufacturing)

- Clinical Sim Setup (courtesy of Broc Burke, WashU School of Medicine)

- Device Operation (courtesy of Dennis Mell, WashU Electrical & Systems Engineering)