Sticky, even when wet

Marcus Foston is helping Fuzhong Zhang understand how novel synthetic biological materials based on mussel feet can be designed for applications that require underwater adhesives

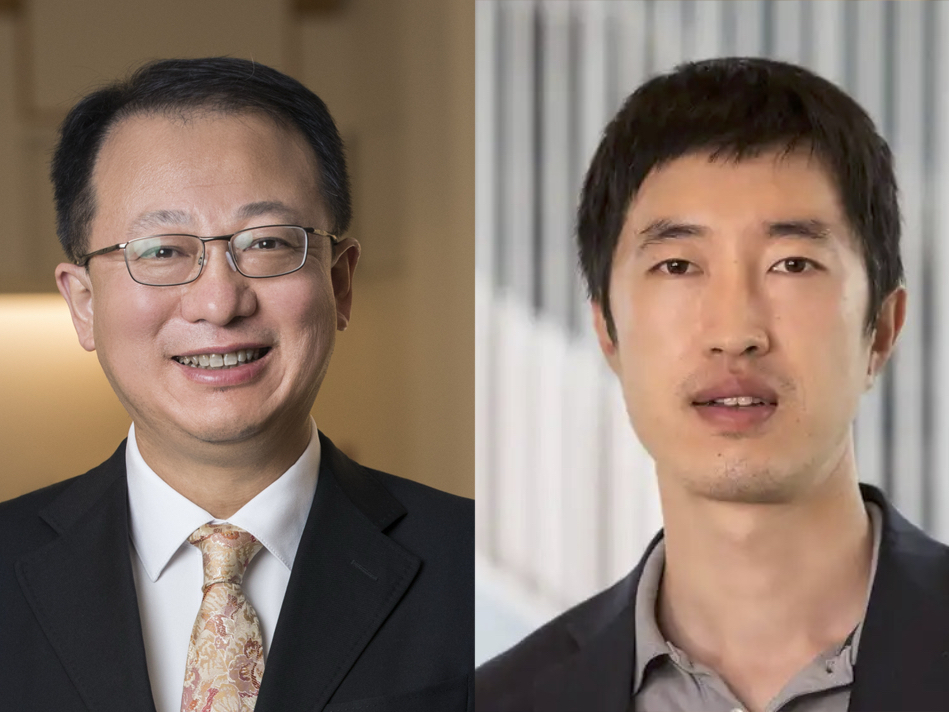

Marcus Foston, associate professor of energy, environmental & chemical engineering in the McKelvey School of Engineering at Washington University in St. Louis, is one of 20 awardees selected by the Environmental Molecular Sciences Laboratory (EMSL) for this year’s Exploratory Call. EMSL is a Department of Energy (DOE) Office of Science national user facility that supports scientific discovery designed to understand complex biological and environmental systems for sustainable solutions to the nation’s energy and environmental challenges.

With EMSL’s support, Foston and his collaborator, Fuzhong Zhang, professor of energy, environmental & chemical engineering in McKelvey Engineering, will develop an understanding of how to redesign and recombine proteins based on protein sequences found in mussel feet. Borrowing mussels’ unique ability to stick to just about anything, even when fully submerged in water, the team aims to produce hydrogels with enhanced properties engineered for applications that require underwater adhesives, such as boat repair or surgical glue.

“A lot of people use synthetic biology in the production of biofuels, and that’s definitely an important application, but when I look at nature, I see how nature makes different functional materials,” Foston said. “For example, spider silk exhibits an extraordinarily high strength and toughness, while mussels can secrete proteins that provide them permanent adhesion to solid surfaces in wave-swept seashores.”

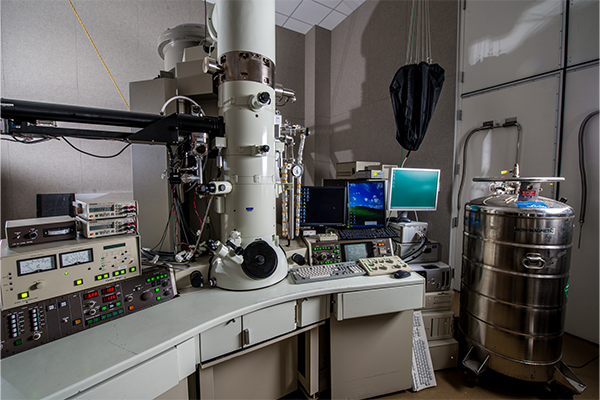

Foston and Zhang apply their combined expertise in synthetic biology and materials science to craft new materials combining the properties of materials found in nature to achieve ideal properties for a particular application. With this award from EMSL, they gain access to sophisticated equipment and analytical tools related to structural biology and materials, as well as experts trained in using that advanced equipment.

“We can leverage those capabilities to glean unique insight about the materials we’re producing,” Foston said. “In particular, this proposal has given us access to methods that allow us to look at the structure of and interaction between different protein segments that we’re putting together. Ultimately, we want to develop sequence-structure relationship. Sequence leads to structure and ultimately to mechanical properties that we’re trying to manipulate.”

Foston and Zhang’s exploration of synthetic biological materials is part of a series of funded projects. Beyond advanced adhesives, Foston is working on synthetic biological materials as an approach to issues related to plastic waste and sustainability.