For success in bioelectronics, build with nature-inspired design

Alex Rutz’s lab creates bioelectronic scaffolds in a unique way

In addition to making gadgets and game pieces, 3D printing is being used in health care to print prosthetics, dental implants and surgical models. Now, a team at Washington University in St. Louis, is using 3D printing to create bioelectronic scaffolds that would allow researchers to create new tissue with a host of potential applications.

Alexandra Rutz, assistant professor of biomedical engineering in the McKelvey School of Engineering, and Somtochukwu Okafor, a doctoral student in Rutz’s lab, have 3D printed bioelectronic scaffolds that have the properties cells need to form new tissue.

“Most traditional scaffolds have been on materials that have been inspired by nature, but here, we are taking that concept and applying it to what we call functional materials,” Rutz said. “These are materials that are designed to perform a certain function, such as being electronically conducting.”

The bioelectronic scaffolds that Rutz and Okafor print appear as dark-colored dots about 6 millimeters in diameter — about the size of a pencil eraser — and are floating in water. Okafor has carefully created these tiny scaffolds with a polymer known as PEDOT:PSS, which she has processed into a water-based gel used as an ink.

“When you think of electronics, you aren’t thinking of them being in water,” Okafor said. “But that’s an advantage of using PEDOT:PSS as the conducting material. We are creating hydrated electronics that maintain their electronic properties in an environment that can also sustain living systems.”

Okafor, a fifth-year doctoral student in biomedical engineering, said while their team isn’t the only one using this process, their work is unique.

“Bioelectronics as a field isn’t new — think cochlear implants, pacemakers and smartwatches — but we are trying to interface with biology to make the technology more like systems that would occur in nature,” Okafor said. “We have borrowed approaches in 3D printing and tissue engineering and combined it with bioelectronics. All these processes have individual advantages that they bring to the table, and we are combining them into one.”

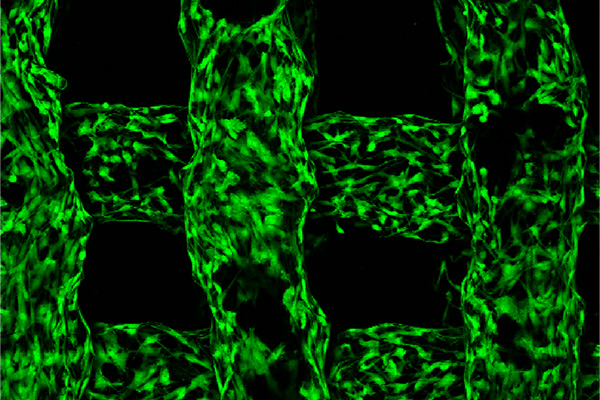

Most traditional materials that conduct electricity are stiff, which may negatively impact formation of tissue. Rutz’s lab created their scaffolds from a soft, conducting hydrogel and with pores that are about 150 microns to 300 microns in size that can influence how cells behave within the scaffold, such as how they attach to others, how they move through the scaffold and how they multiply. The pores help to form a lattice-like structure that grows upward to support the cells. The researchers can also adjust the angle of the pores so that the grid lines are diagonal instead of vertical and horizontal.

“The pores have to be big enough to allow the cells to move around, but small enough that the cells have structure to hold on to and don’t fall through,” Okafor said.

The tissue the team seeks to create could be used as human tissue or plant tissue, making it versatile for several uses.

“We have many projects in the lab that are envisioned for tissues-on-chips technology, where this could be used for drug development purposes, toxicology, environmental toxicity and other projects where human tissues are in a dish,” Rutz said.

In partnership with WashU’s Office of Technology Management, Rutz and Okafor have applied for a patent for the 3D printing of their bioelectronic scaffolds with the U.S. Patent Office.

Okafor SS., Park J, Liu T, Goestenkors AP, Alvarez RM, Semar BA, Yu JS, O’Hare CP, Montgomery SK, Friedman LC, Rutz AL. 3D printed bioelectronic scaffolds with soft tissue-like stiffness. Advanced Materials Technologies, published online Feb. 4, 2025. DOI: https://doi.org/10.1002/admt.202401528

Funding for this research was provided by Washington University in St. Louis; National Science Foundation (FR2319060, CMMI 15-48571).